FRBronze Mesh with PTFE Layer Bearings

Material:a bronze mesh shell, laminated with compounded PTFE tape

- This material structure enables the final parts to be lighter and easier for installation.

- It is widely used in chemical industries, medical industries, food industries, textile machines, OA machines, and door/window hinges etc.

- Standard wall thickness: 0.48 ± 0.02mm, dimensions could be supplied against customer designation.

| Tech. Data | ||||||

|---|---|---|---|---|---|---|

| Max. Load P | Static load | 80 N/mm² | Friction coefficient | 0.03~0.20 | ||

| Dynamic load | 40 N/mm² | Max. Speed | Dry | 1m/s | ||

| Temp. limit | -195℃~+260℃ | Oil | >1m/s | |||

| FR & FD | ||||||

|---|---|---|---|---|---|---|

| FR | FD1 | FD2 | ||||

|

|

|

||||

| Material | It’s a maintenance free bushing material made of a bronze metal mesh, with wear resistant PTFE | It consist of PTFE with bronze powder and additive material. | It’s based on PTFE and filled with graphite and other material. | |||

| Features |

•Excellent strength and loading capacity •Good heat resistance •Low friction |

•Low wear •Low friction •Supply under oil or without oil. |

•Good elasticity •Low friction •high wear resistance |

|||

| Applications | Textile machines, Automotive door hinges, Seat belt preload devices | Auto damper, Piston ring | It fits to be used together with metal backing | |||

| Load capacity | 30N/mm² | 20N/mm² | 20N/mm² | |||

| Temperature | -40℃ to +280℃ | -100℃ to +250℃ | -100℃ to +250℃ | |||

| Speed limit | 2.0 m/s | 1.5 m/s | 1.5 m/s | |||

| Friction coef | 0.05~0.20 | 0.03~0.20 | 0.03~0.20 | |||

| PV limit(oil) | 1.65N/mm²·m/s | 1.2N/mm²·m/s | 1.2N/mm²·m/s | |||

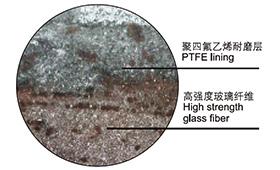

CRseries

- made of high lubricity of special PTFE fiber and high strength artificial synthetic fiber with, even in the absence of external lubrication conditions can still maintain the self lubricity and excellent abrasion resistance; very low friction coefficient, high compressive strength, excellent wear resistance and scratch resistant performance;

- backing is composed of high strength epoxy glass fiber, has good corrosion resistance and can be used for freshwater or seawater;

- can bear dynamic load up to 140MPa, but also can bear the huge impact load, with the vibration absorption and the amount of self-aligning capability;

- bearing materials will be solid lubricating film forming effective in use process, make its work stick shaft phenomenon can not occur;

- materials are non metals, so good insulation and light weight, 75% lighter than steel, lighter than aluminum 30%;

- bearing can be applied in lubrication need but not the use of or inability to use lubricant occasions;

- the temperature range of winding type bearing can be used more widely, from -100 to ~+160 degree centigrade;

- this material has very low water absorption and linear expansion coefficient, basic and steel similar, so it can be used in a variety of air, oil, water and other medium;

- winding type bearing is similar to steel and cast iron thermal expansion rate,even in high temperature conditions is also very stable.

CRB Coffee colour

| CRB Coffee colour | ||||||

|---|---|---|---|---|---|---|

| Technical Description | Unit | CRB | ||||

| Basic type | Standard | |||||

| Density | g/cm³ | 2.00 | ||||

| Max.PV(dry) | N/mm²* m/s | 1.8 | ||||

| Coefficient of friction | 0.03~0.12 | |||||

| Working Temp. | ℃ | -100~+160 | ||||

| Max.Speed | m/s | 0.20 | ||||

| Max.load | MPa | 420 | ||||

| Static load | MPa | 240 | ||||

| Dynamic load | MPa | 140 | ||||

| Radial compressive strength | MPa | 550 | ||||

| Rockwell hardness | HRR | 95 | ||||

| Linear thermal expansion factor | 10-6 *K-1 | 13 | ||||

CRE White colour

| CRE White colour | ||||||

|---|---|---|---|---|---|---|

| Technical Description | Unit | CSB-CRE | ||||

| Basic type | General | |||||

| Density | g/cm³ | 2.00 | ||||

| Max.PV(dry) | N/mm²* m/s | 1.6 | ||||

| Coefficient of friction | 0.03~0.12 | |||||

| Working Temp. | ℃ | -100~+160 | ||||

| Max.Speed | m/s | 0.20 | ||||

| Max.load | MPa | 420 | ||||

| Static load | MPa | 240 | ||||

| Dynamic load | MPa | 100 | ||||

| Radial compressive strength | MPa | 550 | ||||

| Rockwell hardness | HRR | 95 | ||||

| Linear thermal expansion factor | 10-6 *K-1 | 13 | ||||

CRF Dark gray colour

| CRF Dark gray colour | ||||||

|---|---|---|---|---|---|---|

| Technical Description | Unit | CRF | ||||

| Basic type | Economic | |||||

| Density | g/cm³ | 1.30 | ||||

| Max.PV(dry) | N/mm²* m/s | 1.2 | ||||

| Coefficient of friction | 0.08~0.30 | |||||

| Working Temp. | ℃ | -40~+130 | ||||

| Max.Speed | m/s | 0.13 | ||||

| Max.load | MPa | 300 | ||||

| Static load | MPa | 150 | ||||

| Dynamic load | MPa | 45 | ||||

| Radial compressive strength | MPa | 200 | ||||

| Rockwell hardness | HRR | 90 | ||||

| Linear thermal expansion factor | 10-6 *K-1 | 40 | ||||